Products

Category

Robot Grinding WorkShop

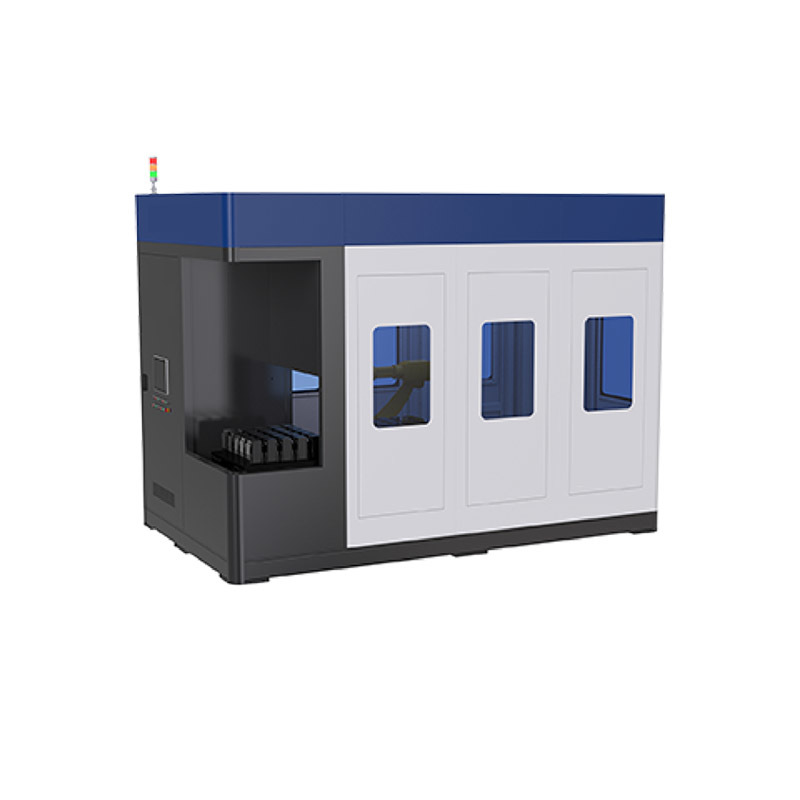

Compared with the disadvantages of traditional polishing and sanding, which is easy to hit the wrong paste, the robot polishing workstation uses real-time force control feedback, precision trajectory adjustment,precision contact force adjustment and other advanced technologies to achieve safe, stable and efficient polishing and sanding operations, overcoming the traditional robot is easy to mistakenly hit the debugging time is long, and the quality of the finished product is inconsistent and other shortcomings, so it has a clear differentiation advantage.

Category: Robot Grinding WorkShop

Keywords: Low Power Grinding Robot | Gantry Grinding Robot

Robot Grinding WorkShop

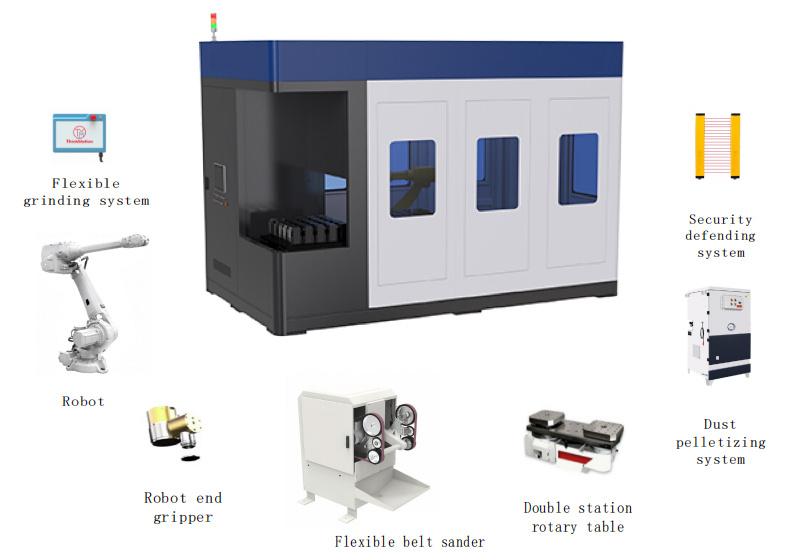

| PRODUCT PARAMETERS | |

| Robot flexible grinding workstation | Robot |

| Robot end gripper | |

| Process formula (abrasive form design + mesh number + grinding times + power actuator + speed + torque + trajectory) | |

| Flexible belt sander | |

| Double station rotary table (customization) | |

| Security defending system | |

| Dust pelletizing system(Optional) | |

| Advantages of workstations | Compared with the disadvantages of traditional polishing and sanding, which is easy to hit the wrong paste, the robot polishing workstation uses real-time force control feedback, precision trajectory adjustment,precision contact force adjustment and other advanced technologies to achieve safe, stable and efficient polishing and sanding operations, overcoming the traditional robot is easy to mistakenly hit the debugging time is long, and the quality of the finished product is inconsistent and other shortcomings, so it has a clear differentiation advantage. |

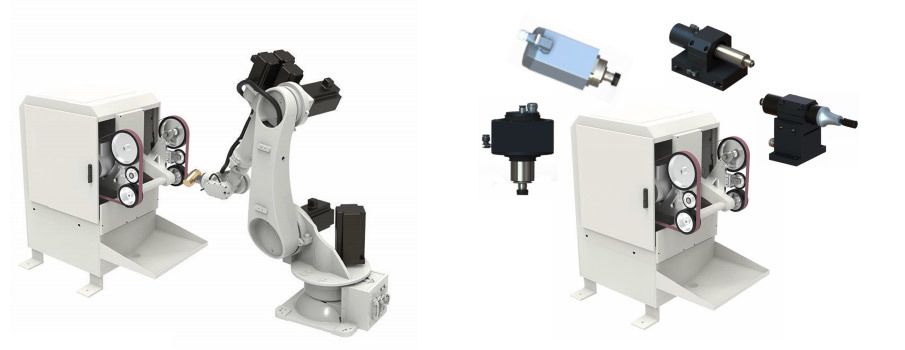

| NO. | Floating pressure | Force control accuracy | Floating range | Positional accuracy | Power | Linear velocity | Abrasive belt width | Voltage | Polishing tools(Optional) |

| 1 | 10-300N | ±3N | 0-20mm | 0.05mm | 5.5KW | 15m/s | 50/75/100mm | 380V | Rigid motorized spindle |

| Axial floating motorized spindle | |||||||||

| Radial floating motorized | |||||||||

| Radial floating file |

Industry case

Equipment Features

1.The highest grinding efficiency, suitable for the surface grinding and polishing of small and medium-sized workpieces such as hardware/die castings/automotive parts;

2.Precision force control control technology can ensure accurate and stability of the contact force, and at the same time can automatically compensate the wear of the sasal consumables according to the process;

3.Quick change system designed for saving time if change the consumptionrm in limit position;

4.The overall weight of the equipment is more than 200KG

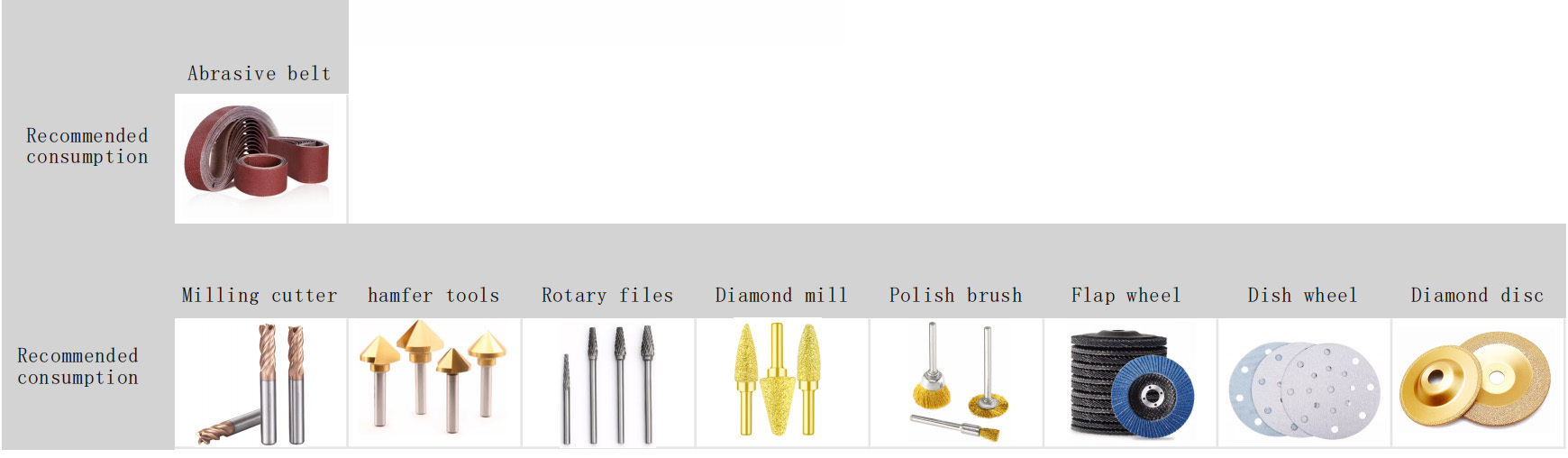

Surface treatment process: grinding, polishing, deburring

Suitable materials: steel, aluminum, copper, titanium, magnesium, plastic, wood, ceramics,carbon fiber, etc

Recommended Products

Online Message

sales@thinkmotion.cn

sales@thinkmotion.cn

Message

Message

sales@thinkmotion.cn

sales@thinkmotion.cn

+8613818783778

+8613818783778