Products

Category

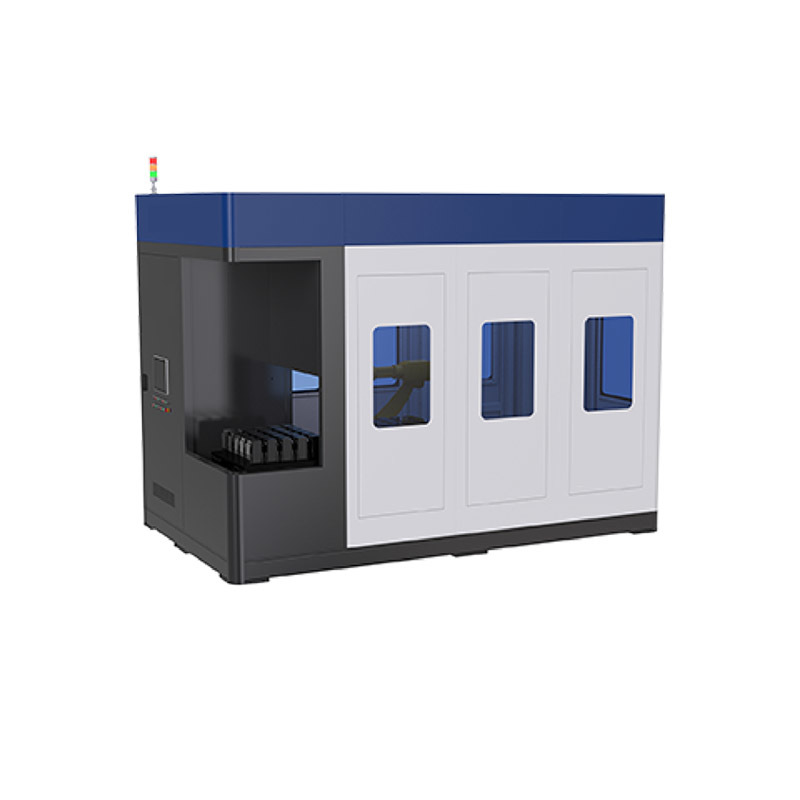

High Power Grinding Robot

The high-power force controlled polishing workstation developed by our company has an independent constant force control system, and the intelligent control actuator can output a constant pressure (force control range: 10~500N, compensation stroke: 20mm), enabling the tool to achieve intelligent full posture constant force floating, easy operation, and flexible polishing according to the usage posture of large floating tools. One polishing tool can be paired with dual electric spindles to solve the problem of two polishing processes; The maximum adaptable power of 4.5kw electric spindle can achieve full attitude force/position hybrid control compensation, suitable for surface treatment of any shape workpiece, and ensure accurate and stable contact force;

Category: High Power Grinding Robot

Keywords: Low Power Grinding Robot | Gantry Grinding Robot

High Power Grinding Robot

Action process:

1. Select the appropriate polishing tool, connect the robot and the force controlled floating device;

2. Configure the coordinate system and parameters of the robot and force controlled floating device;

3. Input the weight and force control compensation direction of the polishing tool;

4. Verify whether the force control function of the robot's various posture angles is intact;

5. Select force control mode and process parameters;

6. Start the polishing action and provide real-time feedback to monitor the polishing force value.

Applicable fields:

Robot high-power force control polishing workstation is a one-stop solution for users to provide high-performance solutions in multiple industries, serving industries such as kitchen and bathroom, automotive parts, sports equipment, medical equipment, 3C, furniture, home appliances, etc; Suitable surface treatment processes: metal weld polishing, mold line polishing, casting sprue polishing, metal wire drawing, aluminum milling, copper milling, aluminum wire drawing, stainless steel mirror polishing, copper mirror polishing; Applicable materials: Grinding and polishing of metals such as cast iron, steel, aluminum, titanium, copper, etc.

Equipment section:

The product includes heavy-duty industrial six axis intelligent robots, high load force control floating execution modules, intelligent force value controllers, and high-power grinding tools (optional high-power grinding dedicated electric spindles and sand belt machines); The workstation can be equipped with robots with a load capacity of 50kg or more according to the actual situation (the figure shows the default standard 155kg load robot); Suitable but not limited to the following consumables.

Advantage features:

The high-power force controlled polishing workstation developed by our company has an independent constant force control system, and the intelligent control actuator can output a constant pressure (force control range: 10~500N, compensation stroke: 20mm), enabling the tool to achieve intelligent full posture constant force floating, easy operation, and flexible polishing according to the usage posture of large floating tools. One polishing tool can be paired with dual electric spindles to solve the problem of two polishing processes; The maximum adaptable power of 4.5kw electric spindle can achieve full attitude force/position hybrid control compensation, suitable for surface treatment of any shape workpiece, and ensure accurate and stable contact force.

Working Range:

Recommended Products

Online Message

sales@thinkmotion.cn

sales@thinkmotion.cn

Message

Message

sales@thinkmotion.cn

sales@thinkmotion.cn

+8613818783778

+8613818783778